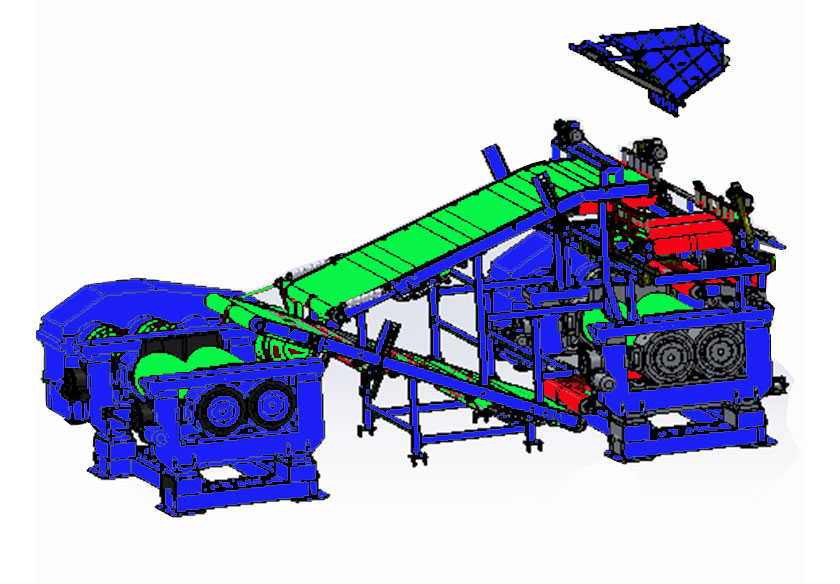

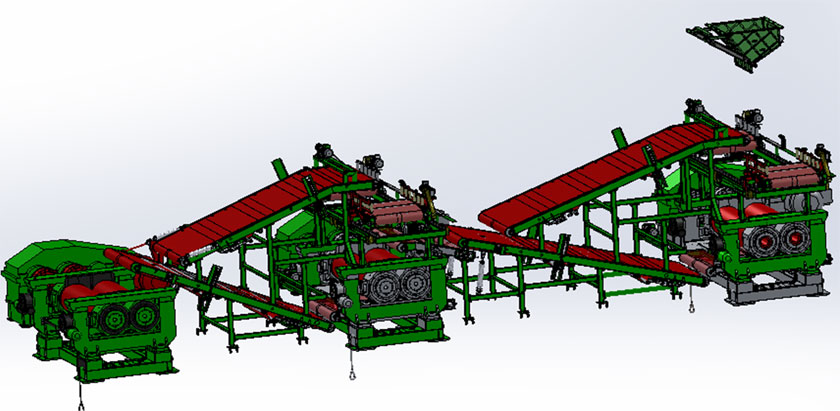

This machine is a part of mixing production line, the auxiliary machine with two rubber mixing machine, two sets of mixing milljoined together, the first configure automatic picking, automatic stock blender, automatic snapping, and other functions, implementation of rubber cooling, mixing, the rubber after the first mixing machine compiete mixing are automatically transported to the second tablet mixing machine, the rubber after two roller pressure by labor to pick up the pieces.

This production line is mainly has the following parts: the mixing mill (own by customers), conveyer belt (the first mixing machine between the second mixing machine), open mixing machine automatic stock blender, scraper device, collecting device, safety protection system and control system

| conveyer belt widht | 2000mm |

| temperature resistance | 140℃ |

| conveyer belt speed | 40m/min |

| conveyer moto power | 3kw |

| belt tension | manual operation |

| belt rectification | cylinder automatic |

| stock blender conveyer belt moto power | 2×3kw |

| rubber swing device moto power | 2×2.2kw |

| rubber swing belt moto power | 2×2.2kw |

| rubber swing conveyer belt width | 1000mm |

| stock blender conveyer belt width | 2000mm |

| linear speed | 40m/min |

| rubber swing amplitude | 1200mm |

| cycle conveyer belt length | 11500mm |